Writer: Eric Bearing Limited

1. What is FAG clutch bearing

The so-called release bearing is the bearing used between the clutch and the transmission, usually we call it "clutch release bearing". When the clutch is stepped on, if the shift fork is combined with the clutch pressure plate that is rotating at high speed, a bearing must be required to eliminate the heat and resistance caused by direct friction. Therefore, the bearing installed at this position is called a release bearing. The release bearing pushes the pressure plate to separate it from the friction plate, thus cutting off the power output by the crankshaft.

2. FAG clutch release bearing performance requirements

The release bearing should move flexibly, without sharp noise or jamming, its axial clearance should not exceed 0.60mm, and the wear of the inner race should not exceed 0.30mm.

3. The working principle and function of FAG clutch release bearing

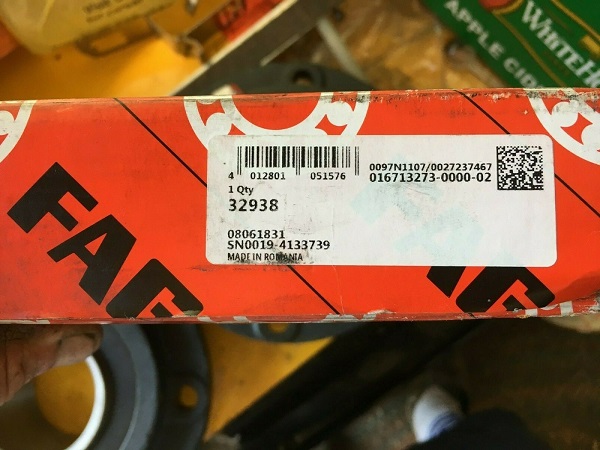

The so-called clutch, as the name implies, means to use "disconnect" and "close" to transmit an appropriate amount of power. The engine is always spinning, but the wheels are not. To stop the vehicle without damaging the engine, the wheels need to be disconnected from the engine in some way. By controlling the slip between the engine and the transmission, the clutch allows us to easily connect the rotating engine to the non-rotating transmission. FAG 32938 bearings online , pls contact us :

The clutch release bearing is installed between the clutch and the transmission. The release bearing seat is loosely sleeved on the tubular extension of the first shaft bearing cover of the transmission. The shoulder of the release bearing is always against the release fork through the return spring and retracts to the final position , Keep a gap of about 3~4mm with the end of the separation lever (separation finger).

Since the clutch pressure plate, the release lever and the engine crankshaft operate synchronously, and the release fork can only move axially along the clutch output shaft, it is obviously impossible to directly use the release fork to dial the release lever. The release bearing can make the release lever rotate side by side. The output shaft of the clutch moves axially, which ensures that the clutch can engage smoothly, disengage softly, reduce wear, and extend the service life of the clutch and the entire drive train.

4. Points to note when using FAG clutch release bearings

(1) In accordance with the operating regulations, avoid the clutch half-engaged and half-disengaged and reduce the number of times the clutch is used.

(2) Pay attention to maintenance. Use the steaming method to soak the butter so that it has sufficient lubricant during regular or annual inspection and maintenance.

(3) Pay attention to leveling the clutch release lever to ensure that the elastic force of the return spring meets the requirements.

(4) Adjust the free stroke to meet the requirements (30-40mm) to prevent the free stroke from being too large or too small.

(5) Minimize the number of joining and separation, and reduce the impact load.

(6) Step on lightly and easily to make it join and separate smoothly.

5. Common factors causing damage to FAG clutch release bearings during use

(1) Working conditions and force of clutch release bearing

The release bearing is subjected to axial load, impact load and radial centrifugal force during high-speed rotation during use. In addition, because the fork thrust and the reaction force of the release lever are not on the same line, a torsional moment is also formed. The clutch release bearing has poor working conditions, intermittently rotating at high speed and bearing high-speed friction, high temperature, poor lubrication conditions, and no cooling conditions.

(2) Causes of damage to the clutch release bearing

The damage of the clutch release bearing has a lot to do with the operation, maintenance and adjustment of the driver. The reasons for the damage are roughly as follows:

a. Working temperature is too high to produce overheating

Many drivers often half-depress the clutch when turning or decelerating, and some have their feet on the clutch pedal after shifting gears; some vehicles have too much free stroke adjustment, which makes the clutch disengagement incomplete and in a semi-engaged and semi-disengaged state. A large amount of heat generated by dry friction is transferred to the release bearing. The bearing is heated to a certain temperature, and the butter melts or dilutes and flows, which further increases the temperature of the release bearing. When the temperature reaches a certain level, it will burn out.

b. Lack of lubricating oil and wear

The clutch release bearing is lubricated with grease. There are two ways to add grease. For the 360111 release bearing, open the back cover of the bearing and fill in the grease during maintenance or when the transmission is removed, and then reinstall the back cover Just close; for the 788611K release bearing, it can be disassembled and immersed in molten grease, and taken out after cooling to achieve the purpose of lubrication. In actual work, the driver tends to ignore this point, causing the clutch release bearing to lack oil. In the absence of lubrication or less lubrication, the wear amount of the release bearing is often several to several tens of times the wear amount after lubrication. As abrasion increases, the temperature will also increase greatly, which makes it more vulnerable to damage.

c. The free stroke is too small or the number of loads is too much

According to the requirements, the clearance between the clutch release bearing and the release lever is 2.5mm, which reflects the free stroke of 30-40mm on the clutch pedal. If the free stroke is too small or there is no free stroke at all, it will cause the separation lever and The release bearing is normally engaged. According to the principle of fatigue failure, the longer the working time of the bearing, the more serious the damage; the more times the bearing is loaded, the easier it is for the release bearing to produce fatigue damage. Moreover, the longer the working time, the higher the temperature of the bearing, the easier it is to burn, which reduces the service life of the release bearing.

d. In addition to the above three reasons, whether the separation lever is adjusted smoothly, and whether the return spring of the separation bearing is good, also has a great influence on the damage of the separation bearing.

6. Maintenance of FAG clutch release bearing

Fix the inner ring of the release bearing by hand, rotate the outer ring, and apply pressure in the axial direction at the same time. If there is blockage or a clear sense of clearance, replace the FAG release bearing. Release bearings are usually filled with grease all at once. Do not disassemble and clean at will during maintenance. If it is dirty, wipe the surface with a clean cloth.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!