Writer: Eric Bearing Limited

1.Size restrictions

Usually the space where FAG bearings can be installed is limited. In most cases, the shaft diameter (or bearing inner diameter) is based on mechanical design or other design limitations. Therefore, the choice of FAG bearing type and size is determined according to the inner diameter of the bearing. Therefore, the main dimension tables of standard FAG bearings are compiled according to the international standard inner diameter dimensions.

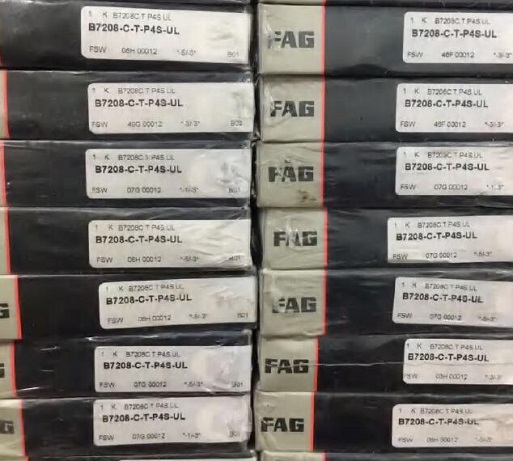

Standard FAG bearings come in a variety of sizes. It is best to use standard FAG bearings in the design of mechanical devices (this is designed to determine whether FAG bearings are easy to purchase. I will say aside from this, some bearing catalogs do have models, but some are not The standard FAG bearing is not available in mainland China, and sometimes the futures will be very long, so the cost of time and the cost of later replacement must be considered when selecting the bearing.) The load of the FAG bearing, the load imposed on the bearing, its nature and size The direction is changeable. Usually, the rated basic load is shown on the dimension table. However, axial load and radial load are also important factors in choosing a suitable bearing. When the dimensions of the ball and needle bearings are equivalent, the needle bearings usually have a higher load capacity and bear larger vibration and shock loads. FAG B7208-C-T-P4S-UL bearings online , pls click here :

2.Speed

The allowable speed is determined by factors such as FAG bearing type, size, accuracy, cage type, load, lubrication method, and cooling method. The FAG bearing table lists the allowable speed of standard precision bearings under oil lubrication and grease lubrication. Generally, deep groove ball bearings, self-aligning ball bearings and cylindrical roller bearings are suitable for high-speed operation.

3.Bearing tolerance.

FAG bearing dimensional accuracy and rotation accuracy are based on ISO and JIS standards. For machinery requiring high precision and high-speed operation, it is recommended to use bearings of grade 5 or higher accuracy. Deep groove ball bearings, radial thrust ball bearings or cylindrical roller bearings are suitable for machines with high operating accuracy. Rigidity, when the rolling elements and raceway contact surfaces of FAG bearings are compressed, elastic deformation will occur. Some machines need to minimize elastic deformation. Roller bearings produce less elastic deformation than ball bearings.

In addition, in some cases FAG bearings must be preloaded to increase rigidity. This procedure is usually used for deep groove ball bearings, radial thrust ball bearings and tapered roller bearings, inner and outer ring offset, shaft bending, shaft or bearing box tolerance changes, fit errors will cause eccentricity of the inner and outer rings. In order to prevent the eccentric angle from being too large, self-aligning ball bearings, self-aligning roller bearings, or self-aligning bearing seats are the better choices. Voice frequency and torque, rolling bearings are manufactured according to high-precision standards, so the voice and torque are small. Deep groove ball bearings and cylindrical roller bearings are suitable for occasions with special requirements for low noise and low torque.

Usually the space where FAG bearings can be installed is limited

In most cases, the shaft diameter (or bearing inner diameter) is based on mechanical design or other design limitations. Therefore, the choice of bearing type and size is determined according to the inner diameter of the FAG bearing. Therefore, the main dimension tables of standard FAG bearings are compiled according to the international standard inner diameter dimensions.

There are many sizes of standard bearings. It is best to use standard FAG bearings in the design of mechanical devices (this design is whether the bearings are easy to purchase. Let me just say something off-topic. Some FAG bearing catalogs do have models, but some non-standard FAG bearings are not available in mainland China, and sometimes the futures will take a long time, so the time cost and the cost of later replacement should be considered when selecting the bearing) The load of FAG bearings, the load imposed on the bearings, its nature, size, The direction is changeable. Usually, the rated basic load is shown on the dimension table. But axial load and radial load are also important factors in choosing a suitable FAG bearing. When the dimensions of the ball and needle bearings are equivalent, the needle bearings usually have a higher load capacity and bear larger vibration and shock loads.

After the installation of FAG bearings is completed, in order to check whether the installation is correct, a running inspection is required.

Small machinery can be rotated by hand to confirm whether it rotates smoothly. The inspection items include poor operation due to foreign objects, scratches, and indentations, unstable torque due to poor installation, poor processing of the mounting seat, excessive torque due to too small clearance, installation errors, and seal friction, etc. Wait. If there is no abnormality, power operation can be started.

Large machinery cannot be rotated manually, so the power is cut off immediately after no-load start, the machine is idling, check whether there is vibration, noise, whether the rotating parts are in contact, etc. After confirming that there is no abnormality, enter the power operation.

Whether the installation of FAG bearings affects the performance and life of bearings

Bearings are one of the important components on construction machinery. Poor installation will affect their use and even cause failure of construction machinery equipment.

If foreign materials such as iron filings, burrs, and dust enter the FAG bearing, it will cause noise and vibration during operation of the FAG bearing, and may even damage the raceway and rolling elements. Therefore, before installing FAG bearings, the installation surface and the installation environment must be clean.

Lubrication has a very important effect on the operation and life of bearings. Grease is made from base oil, thickener and additives. The performance of the grease is mainly determined by the base oil. Generally low viscosity base oil is suitable for low temperature and high speed; high viscosity is suitable for high temperature and high load.

Thickener is also related to lubricating performance, the water resistance of the thickener determines the water resistance of the grease. In principle, greases of different brands cannot be mixed, and even greases of the same type of thickener can cause bad effects due to different additives. The surface of the FAG bearing is coated with anti-rust oil. It must be carefully cleaned with clean gasoline or kerosene, and then coated with clean high-quality or high-speed high-temperature lubricating grease before installation. Fully enclosed FAG bearings do not need to be cleaned and oiled.

After the FAG bearing is installed, if it is not carefully adjusted, the alignment may cause the FAG bearing to suffer additional loads, friction and vibration. These may accelerate fatigue and reduce the service life of FAG bearings, and may damage the service life of other machine parts. In addition, increased vibration and friction may greatly increase energy consumption and the risk of premature failure.

During use, the basic external conditions of FAG bearing operation must be monitored frequently, such as temperature, vibration and noise measurements. These regular inspections will detect potential problems early and will prevent unexpected machine stoppages, enable production planning to be realized, and increase plant productivity and efficiency.

During operation, FAG bearings require correct relubrication to perfect its performance. The method of FAG bearing lubrication is divided into grease lubrication and oil lubrication. In order to make FAG bearings function well, first of all, it is necessary to choose a lubrication method suitable for the conditions of use and purpose of use. If only lubrication is considered, the lubricity of oil lubrication is dominant. But grease lubrication has the advantage of simplifying the structure around FAG bearings.

The most important component of the FAG bearing plunger pump for hydraulic pumps is the bearing. Reducing the negative pressure in the FAG bearing is the basic requirement to prevent water from entering. The load calculation of the angular contact bearing. The oil supply maintenance of the locomotive bearing is very important.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!