Writer: Eric Bearing Limited

The clearance of spherical roller bearings refers to the maximum distance that the inner and outer rings of the bearing can move without load, that is, when the bearing is not assembled in the shaft or bearing box, the inner ring or the outer ring is fixed. The amount of movement when moving the unfixed side in the radial or axial direction. According to its moving direction, the radial clearance is called radial clearance, and the axial clearance is called axial clearance.

1. The radial clearance of spherical roller bearings will change correspondingly under different conditions, so it can be divided into original clearance, assembly clearance and working clearance:

(1) The original clearance refers to the clearance in the free state after the bearing is assembled before being assembled in machinery and equipment. It is determined by the manufacturer's processing and assembly.

(2) The assembly clearance is also called the fit clearance, which is the clearance when the bearing is assembled with the shaft and the bearing seat and has not yet worked. Mainly because of interference assembly, or the inner ring is increased, or the outer ring is reduced, or both, the assembly clearance is smaller than the original clearance.

(3) Working clearance is also called effective clearance, which refers to the actual clearance existing in the bearing after the bearing is assembled in the host machine and the corresponding temperature rise and stable operation are achieved under the corresponding load effect. The working clearance is smaller than the original clearance, but compared with the assembly clearance, it is mainly because the inner ring has the largest temperature rise and the largest thermal expansion during operation, which reduces the bearing clearance. At the same time, it is mainly because of the effect of the load The elastic deformation of the contact between the rolling element and the raceway increases the bearing clearance, which is actually larger or smaller than the assembly clearance, depending on the combined effectiveness of these two factors.

2. The choice of clearance

(1) Spherical roller bearings are more rigid than ball bearings. To avoid radial seizure due to the temperature difference between the inner and outer rings, the spherical roller bearings should retain a certain radial clearance. For bearings that require rigidity or rotational accuracy, such as double-row angular contact ball bearings for automobile hubs, a certain amount of pretension is required to form a "negative clearance".

(2) Light load, high speed, high precision, low operating temperature

3. Measurement of clearance

The bearing clearance measurement adopts a special clearance measuring instrument, and it can also be fully measured with a feeler gauge or a dial gauge.

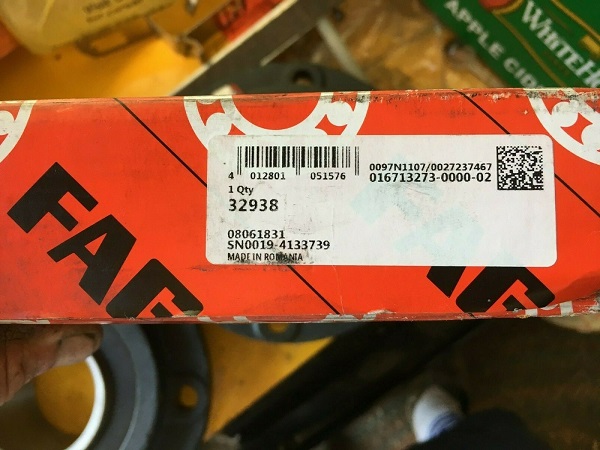

Check with a feeler gauge to verify the maximum load position of the spherical roller bearing. Insert the feeler gauge between the rolling element 180° and the outer (inner) ring. The thickness of the feeler gauge with appropriate elasticity is the bearing radial travel. Gap. This specific method is generally applicable to spherical bearings and cylindrical roller bearings; measured with a dial indicator, first adjust the dial indicator to zero, then lift the outer ring of the spherical roller bearing, the dial indicator reading is the bearing Radial clearance. FAG 32938 bearings online , pls click here :

Hazard of unsuitable working clearance of spherical roller bearings

Working clearance is an important quality index of spherical roller bearings and an important parameter in bearing applications. In actual use, the working clearance of the bearing will affect the load distribution, vibration, noise, friction torque and life of the bearing. Inappropriate working clearance of bearings will cause harm to equipment.

1. The working clearance of the bearing is too small.

If the working clearance of the bearing is too small, it will increase the friction torque of the bearing, thereby generating a large amount of heat, which is easy to cause heat damage to the bearing. This is because when the working clearance of the bearing is too small, it will result in poor lubrication of the rolling elements of the bearing and the inner and outer rings of the bearing. A large amount of heat is generated due to dry friction, resulting in wear, cementation, and cracking of the inner and outer rings of the bearing. The bearing is damaged.

2. The working clearance of the bearing is too large.

The working clearance of the bearing is too large, which is mainly caused by the large natural clearance of the bearing and the insufficient pressing force of the bearing. For example, in a high-speed reducer, when the natural clearance of the bearing is large, the working clearance is also relatively large, which will cause the reducer to vibrate greatly during operation and reduce the service life of the bearing.

Adjustment of spherical roller bearing clearance

Adjustment of axial clearance of spherical roller bearings

The inner ring of the bearing is positioned by the shaft shoulder, the outer ring is preloaded by the bearing glands on both sides, and the axial clearance of the bearing is adjusted by the preload of the bearing glands on both sides, taking into account the clearance caused by the heat of the bearing To reduce, there should be a certain clearance in the axial direction of the bearing. There is no relevant standard for the axial clearance of the bearing.

In practice, the axial clearance is less affected by factors such as interference assembly and operation under load. Therefore, during installation, the original clearance of the bearing is generally adjusted as a standard.

Adjustment of Spherical Roller Bearing Radial Clearance

The radial clearance of the bearing plays a vital role in the stable operation of the bearing, and for the radial clearance of the bearing, GB/T4604-2006 has relevant standards, so in specific applications, only need to look up the table to know The upper and lower limits of the radial clearance of the bearing.

The specific adjustment method: In order to facilitate the measurement, the glands on both sides of the bearing should be removed before adjustment, the bearing should be installed on the bearing seat, the upper cover should be covered, and the four tightening bolts on both sides of the bearing should be evenly tightened using a torque wrench. The force can refer to the relevant provisions of the national standard. After tightening in place, use a feeler gauge to measure. The measured value is compared with the standard value of the look-up table.

Because there are many factors that affect bearing clearance, there are also many specific adjustment methods for bearing clearance. Only some of them are mentioned in this article. Different methods can be used to adjust each bearing in different parts of use.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!