Writer: Eric Bearing Limited

Whether the NACHI machine tool spindle bearing is installed correctly determines the life, accuracy and performance of the bearing.

The steps to install the spindle bearing are as follows: a first check the shaft and bearing seat b unpacking and cleaning c installation d confirmation after installation.

Bearing seat inspection

Thoroughly clean the shaft and bearing seat to remove dust or debris. Also check for cracks and burrs.

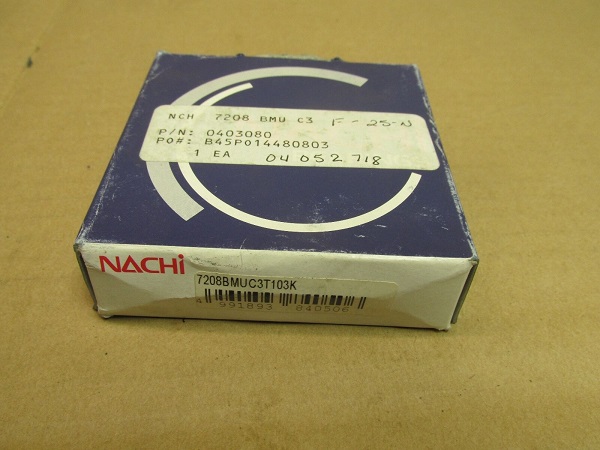

Check and record whether the dimensions of the shaft and the bearing seat, and the verticality of the shaft shoulder fillet meet the requirements of the drawing. Measure 2 positions in the axial direction and 4 positions in the circumferential direction. NACHI 7208BMUC3 bearings online , pls click here :

Shaft diameter and bearing housing inner diameter measurement location unpacking and cleaning

Do not open the package of the bearing before use. Please wear latex gloves when unpacking. Opening the bearing package without wearing latex gloves can cause dust to enter the bearing or cause rust.

The surface of the unpacked bearing is coated with anti-rust oil. Please use kerosene or clean gasoline for cleaning. When cleaning, use a spray with filtering or use a rough washing tank and a fine washing tank with a metal mesh at the bottom of the tank for cleaning.

Cover the cleaned bearing with a dust cover after degreasing. Do not rotate the bearing after degreasing.

The storage and handling of NACHI bearings. NACHI spindle bearings are precision parts. Therefore, be careful to prevent damage caused by vibration. Care should also be taken to prevent dirt or rust during storage and transportation.

The bearings should be stored in a cool, dry place away from direct sunlight.

Do not place the bearing directly on the ground. The bearing should be kept on a shelf 30cm above the ground to prevent dust accumulation.

Inventory management should be first in, first out. At the time of shipment, products with an earlier packaging date will be shipped.

When handling the bearing, be careful to collapse or fall. Avoid bearing damage caused by impact. Deformation or damage to the package may cause dust to enter.

Generally, the bearings installed on the machine tool have interference fit on the shaft and clearance fit on the bearing seat. The methods of mounting the bearing on the shaft include thermal expansion method and press fitting method.

Thermal expansion method is a method of heating and expanding the bearing above the interference between the shaft and the inner ring. The use of induction heaters with degaussing devices or heating baths can not impose undue stress on the inner ring and shorten the operating time. The heating temperature must not exceed 120 degrees. Otherwise it will reduce the hardness of the bearing steel and shorten the life of the bearing. Install the heated bearing on the shaft. The cooling axis will also Shrink, there will be a gap between the inner ring and the shaft shoulder, lock it with a nut.

Press fit method

Use a clamp to hold the end face of the inner ring and press into the shaft with a press or jack. Do not apply force to the outer ring or cage when pressing the inner ring. Especially when installing angular contact ball bearings, applying force to the opposite direction of the contact angle will cause damage to the track shoulder and the ball. Please avoid it. The press-in ball of the inner ring may be damaged

Installation direction of NACHI angular contact ball bearings

Reference: The maximum radial runout position is marked on the end faces of the maximum radial runout position of the outer ring and inner ring. Align the minimum shaft runout position with the marked position on the inner ring to minimize shaft runout. The same is true for the outer ring, and the minimum runout position of the bearing seat must be aligned with the marked position of the outer ring. In addition, the assembly of the "V" mark position of the outer ring and the outer diameter surface indicates the "<" position Irrelevant.

Maximum radial jump image

Maximum radial runout position reference: Installation and disassembly force The force required to press the inner ring of the bearing into the shaft (medium solid) or disassembly depends on the interference or the degree of shaft machining, but it can be roughly calculated by the formula. Ka: Press fit force or disassembly force (KN) fk: Coefficient under different installation and disassembly conditions Δde: Effective interference (mm) B: Inner ring nominal width (mm) d: Bearing nominal inner diameter (mm)di: Average inner ring outer diameter (mm) Cylindrical roller bearing, other bearings, here D: Nominal outer diameter of bearing (mm)

Coefficient condition fk (average value) of different installation and disassembly conditions The inner ring is pressed into the cylindrical solid shaft and the inner ring is pulled out from the cylindrical solid shaft) This value is the value when the bearing inner diameter and the shaft surface are coated with a thin layer of lubricant.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!