Various Lubrication Devices in NSK Bearings

Writer: Eric Bearing Limited

1. Manually lubricated NSK bearing lubrication device

The manual lubrication device is simple and easy to use. Open a lubrication hole in the part that needs to be lubricated and you can use an oil can or a gun to refuel. Generally used for low-speed, light-load simple and small machines, such as various calculators, small motors, and sewing machines.

2. Dripping oil NSK bearing lubrication device

For example, the drip-type oil cup, relying on the weight of the oil to drip oil to the lubricated part, is simple in structure and convenient to use. The disadvantage is that the amount of oil is not easy to control. Mechanical vibration, temperature changes and the level of the liquid level will change the amount of dripping.

3. NSK bearing lubrication device for oil pool

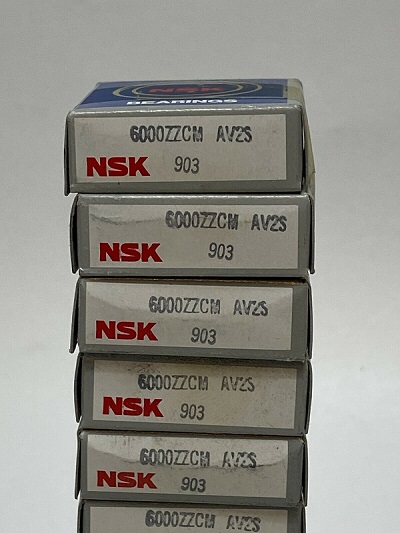

Oil pool lubrication is to set the parts to be lubricated in a sealed box, so that part of the parts that need to be lubricated are immersed in the oil in the oil pool. The parts lubricated by the oil pool include gears, rolling bearings and sliding thrust bearings, sprockets, cams, wire ropes, etc. The advantage of the oil pool lubrication is that it is automatic and reliable, and the oil is sufficient; the disadvantage is that the internal friction loss of the oil is large, and it causes heat generation, and condensation water may accumulate in the oil pool. NSK 6000 ZZCM bearings online , pls click here

4. Splashing NSK bearing lubrication device

Use high-speed rotating parts or rely on additional parts to splash the oil in the oil pool into droplets to supply oil to the friction parts. The advantage is that the structure is simple and reliable.

5. NSK bearing lubrication of oil rope and oil pad

Immerse in oil with wick, felt pad or foam plastic, and use the siphon effect of capillary to supply oil. The wick and the oil pad themselves can play the role of filtering, which can keep the oil clean and continuous and even. The disadvantage is that the amount of oil is not easy to adjust, and it must be noted that the wick cannot contact the moving surface. So as not to be caught between the friction surfaces. Suitable for low and medium speed machinery.

6. NSK bearing device lubricated by oil ring and oil chain

It is only used for the lubrication of horizontal shafts, such as fans, motors, and machine tool spindles. The method is simple. The oil is carried from the oil pool to the shaft to the lubrication part by the ring or chain sleeved on the shaft. The oil ring lubrication is suitable for the speed of 50 -3000r/min horizontal axis. Oil chain lubrication is most suitable for low-speed machinery, but not for high-speed machinery.

7. NSK bearing lubrication device with forced oil delivery

The forced oil delivery lubrication device is divided into:

(1) No circulating lubrication

The oil passing through the friction surface is no longer recycled and used for lubrication points of various equipment that require less oil.

(2) Circulating lubrication

The oil pump sends the oil pressure from the oil pool to each movement pair for lubrication, and the lubricated oil returns to the fuselage oil pool for recycling.

(3) Centralized lubrication

A central oil tank supplies oil to dozens or more lubrication parts, which is used for mechanical equipment with a large number of lubrication points and even the entire workshop or factory. It can be operated manually, or it can automatically distribute the right amount of lubricant at the adjusted time.

Forced lubrication is to use a pump to send oil pressure to the lubricating part, which has good lubrication and cooling effects. Easy to control the size of the oil supply and reliable. It is widely used in large-scale, heavy-duty, high-speed, precise and automated machinery and equipment.

8. Sprayed NSK bearing lubrication device

The oil is atomized by compressed air, and then sprayed onto the lubricated surface through a nozzle. Since compressed air and oil mist are sent to the lubrication part together, there is a better cooling effect. And because the compressed air has a certain pressure, it can prevent the friction surface from being contaminated by dust. The disadvantage is that the discharged air contains oil mist particles, causing pollution. Spray lubrication is used for high-speed rolling bearings and enclosed gears and chains.

The advantages of the oil lubrication method are: the oil has good fluidity, good cooling effect, easy to filter and remove impurities, can be used for lubrication in all speed ranges, long service life, easy to replace, the oil can be recycled, but its disadvantage is that the seal is compared difficult.

Grease lubrication device for NSK bearings

1. Manually lubricated NSK bearing unit

Use a grease gun to inject grease from an oil injection hole or directly fill it into the lubrication part by hand. It is a pressure lubrication method, which is used for high-speed operation and does not require frequent replenishment of grease.

2. Drip lubrication device

Put the grease in the grease cup and drip the grease to the lubrication part for lubrication. The fat cup is divided into heating type and pressure type.

3. Centralized lubrication device

The grease in the grease tank is transported to the various pipelines by the grease pump, and then the grease is regularly and quantitatively distributed to the lubrication points through the distribution valve. Used in workshops or factories with many lubrication points.

Compared with lubricating oil, grease has poor fluidity and cooling effect, and impurities are not easy to remove. Therefore, grease is mostly used in low and medium speed machinery.

4. Solid-lubricated NSK bearing device

There are generally four types of solid lubricants, namely, integral lubricants, coating lubricants, combination, composite lubricants and powder lubricants. If the solid lubricant is mixed in the oil or grease in powder form, the lubrication device can use the corresponding oil or grease lubrication device. If the cover film, combination, composite material or integral part lubricant is used, no lubrication device is needed. Achieve lubrication.

5. Gas-lubricated NSK bearing device

Air lubrication is generally a forced air lubrication system. For example, the gas bearing system, the entire lubrication system is composed of air compressor, pressure reducing valve, air filter and pipeline.

In short, in the lubrication work, the choice of lubrication methods and devices must be based on the actual conditions of the mechanical equipment, that is, the structure of the equipment, the motion form of the friction pair, the speed, the load, the degree of precision, and the working environment.