Writer: Eric Bearing Limited

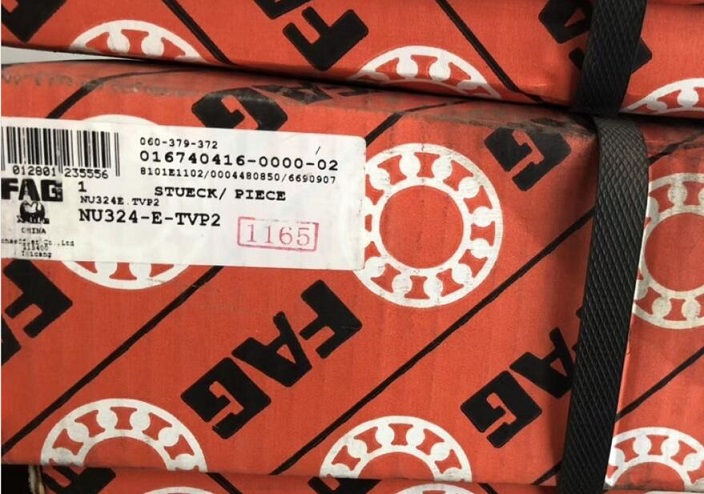

The additional sealing device supported by the bearing can effectively prevent the intrusion of foreign objects, but this additional sealing device will increase the axial size of the mechanism, which will bring inconvenience to the use and installation and maintenance of the bearing. The influence of the machining accuracy and line position tolerance of matching parts. The bearing with seal can not only have a good sealing and lubrication environment, but also solve the problem of the supporting part, and at the same time can also save the complicated lubrication system. Therefore, it is recommended to use sealed bearings in the parts with compact structure and strict sealing requirements. In addition to the good dustproof and sealing effect, the self-sealing of the bearing can also maintain a good operating state without replenishing lubricant during the operation of the bearing, reducing maintenance costs. Eric Bearing Ltd have rich stock for FAG NU324-E-TVP2 , if interested , pls contact :

The self-sealing of bearings is divided into contact and non-contact seals according to the structure. According to the contact form, it can be divided into radial seal and axial seal. According to the structure of the sealing ring, it can be divided into single lip seal and double lip seal. Non-contact seals are generally available with a dust cover and a rubber seal. The dustproof cover has a large sealing gap and is only suitable for dustproofing. The rubber sealing ring has a small sealing gap and has a good sealing effect. Contact sealed bearings generally only have rubber seals and extremely auxiliary parts. The lip of the rubber seal ring is in interference contact with the rotating part of the bearing with a certain fitting force, thereby playing a good dust-proof sealing effect, but its lower limit speed and larger friction torque.

FAG bearing running quality inspection

The FAG bearing should be inspected after installation. It should be ensured that the FAG bearing is installed in place, rotates flexibly, and does not get stuck. If the bearing is improperly installed, the temperature of the FAG bearing will rise rapidly and be damaged, and even major accidents such as bearing seizure and fracture will occur.

First,large machinery cannot be rotated manually, so the power is cut off immediately after no-load start, the machine is idling, check for vibration, noise, whether there is contact between rotating parts, etc., and confirm that there is no abnormality, then enter the power operation.

Second,the rotation sound of FAG bearings is checked with a stethoscope, etc., and there are strong metal noises, abnormal sounds, and irregular sounds that indicate abnormalities. The reasons are poor lubrication, poor precision of the shaft or bearing housing, bearing damage, foreign matter intrusion, etc.

Third,the inspection items include poor operation due to foreign objects, scratches, and indentation, unstable torque due to poor installation, poor processing of the mounting seat, torque due to too small clearance, installation errors, and sealing friction Too big, etc. If there is no abnormality, power operation can be started. Small machinery can be rotated by hand to confirm whether it rotates smoothly.

Fourth,the temperature of FAG bearings gradually increases from the beginning of operation, and the temperature is usually stable after 1 to 2 hours. If the bearings are not properly installed, the temperature will rise sharply and abnormally high temperatures will appear. The reasons are too much lubricant, bearing clearance is too small, poor installation, excessive friction of the sealing device, etc. In the case of high-speed rotation, the wrong choice of bearing structure and lubrication method is also the reason. FAG bearing temperature can generally be estimated based on the external temperature of the bearing housing. However, it is more accurate to use the oil hole to directly measure the temperature of the outer ring of the bearing.

FAG bearing life and basic dynamic load rating

1.FAG bearing basic rating life

A batch of the same FAG bearings, running under the same stress, rotation and other conventional conditions, of which 10% of the bearings have fatigue pitting damage (90% of the bearings do not show pitting damage), one bearing is turned The total number of revolutions (revolutions) or working hours is called the basic rating life of the bearing. Use the symbol L (106r) or Lh (h). It should be noted that: ①The conditions of bearing operation are different. If the force is different, the basic rated life value is different; ②The probability that a bearing can reach or exceed this life value is 90% reliability. The probability of not reaching this life value is a destruction rate of 10%.

2.FAG bearing life

Under the action of a certain load, the rolling FAG bearing runs to any rolling element or ring raceway before fatigue pitting occurs. The total number of revolutions (turns) or working hours of the two rings running relative to each other is called bearing life. This also means that a new bearing can no longer be used until it has fatigue pitting. Just like predicting a person's life, we cannot predict the exact life of a specific bearing. But with the help of census and other relevant data, it is possible to predict the lifespan of a certain group of people. Similarly, the following statement about the basic rating life is introduced.

3. Basic dynamic load rating

The basic dynamic load rating refers to the maximum load that FAG bearings can bear when the basic rating life is L = 106r, which is represented by the letter C. The greater the basic dynamic load rating, the greater its carrying capacity. The basic dynamic load rating C value of different types of FAG bearings can be found in the bearing catalog or design manual.

Regular lubrication and maintenance of FAG bearings during operation

1.Grease lubrication

Bearing relubrication is best carried out during planned equipment downtime and is regularly replenished. At the same time,the old grease is removed or the old grease is squeezed out through the oil drain. Wipe the grease nipple clean before adding fresh grease. If the bearing box does not have a grease nipple, the bearing box cover or end cover should be opened to remove the old grease, and after cleaning, add fresh grease of the same model.

2.Lubricating oil

Regularly check the oil level and quality of the lubricating oil. Under normal circumstances, the normal oil level should be within the range of 1 / 3-2 / 3 of the equipment oil level window or mark. The oil filling method is oil cup, and the oil level displayed only represents the oil filling capacity, while the oil level of the bearing box meets the operating requirements. The oil level in the oil cup is less than 1/4 of its total volume.

Inspection and replenishment methods, take a small amount of lubricating oil as a sample and compare with fresh lubricating oil, capable units may consider conducting oil quality tests to ensure that the oil quality is qualified. If the sample looks cloudy, it may be the result of mixing with water, that is, the oil emulsification that everyone often says, and the lubricant should be replaced at this time.

If the sample course becomes darker in color or thicker, it may indicate that the lubricating oil has begun to carbonize, and the old lubricating oil should be completely replaced. If possible, flush the oil line with fresh lubricating oil. When replacing the lubricant, make sure that the new and old models of the replaced lubricant are the same, and supplement the oil level that meets the requirements.

Use an oil-bath lubrication system. If the oil temperature is below 60°C (140°F) and the lubricant is not contaminated, replace the lubricant once a year. If the oil temperature is 60-100°C (140-210°F), the lubricant needs to be changed four times a year. If the oil temperature is between 100-120°C (210-250°F), the lubricant needs to be changed once a month. If the oil temperature is above 120°C (250°F), the lubricant needs to be changed once a week.

Correct installation and maintenance is an important factor for the normal operation of the bearing. At the same time, care must be taken to maintain the cleanliness of the bearing. Bearings must be protected from contaminants and moisture, and must be properly installed and lubricated. In addition, the design of the bearing arrangement, the condition of the oil seal, the form of the lubricant and the replacement cycle and special maintenance also play an important role and must be paid attention to.

FAG rolling bearing parts processing characteristics

FAG bearing parts are short and thin rotating surface bodies. The rotating body determines that the processing machine is relatively single, most of them are lathes and grinding machines; short and thin determine their axial rigidity, axial deformation can be ignored, radial rigidity Poor, special consideration should be given to the tightening method during processing.

Although the structure of rolling bearing parts is simple,but the technical requirements are very high, it has the following processing characteristics:

1.Multi-process processing

FAG bearing parts have high requirements,and there are bound to be many production processes.General bearing production requires 20 to 40 procedures, more than 70 procedures.

2.Precision machining

Most of the surfaces of FAG bearing parts have to be ground. The size and geometric accuracy of the grinding are in μM. Especially the precision of the raceway and rolling elements of the ring is higher, and it needs super-finishing or grinding. Eric Bearing Ltd have rich stock for NU 312-E-XL-JP3 .

3.Molding

The working surfaces of FAG bearing parts are all rotary forming surfaces, which are suitable for processing by forming method. For example, the forging, rolling and turning of the ferrule raceway are processed with forming tools or anti-profile plates.

In addition, the vast majority of bearings are standardized products. The same type of FAG bearings are in great demand. In order to improve productivity, reduce costs, ensure quality and widely use new technologies, improve mechanization and automation, bearing companies generally follow the bearing model The varieties are mass produced, and even special automatic lines or assembly lines can be established for production.

FAG bearing stiffness

The stiffness of FAG bearings refers to the degree of elastic deformation of FAG bearings under load. This deformation is generally small and can be ignored. But in some applications, such as bearings for machine tool spindles or pinion bearings, stiffness is very important.

Cylindrical roller or tapered roller bearings and other roller bearings, because of the linear contact between the rolling elements and the raceway, the rigidity is higher than the point contact ball bearings. Bearing rigidity can be increased by applying preload.

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!