Writer: Eric Bearing Limited

Most of the FAG bearings used in the previous machinery industries are still balls and needles. Only a small part of them have used self-lubricating FAG bearings. It is believed that in the near future, FAG bearings will come from lubricated FAG bearings with strong adaptability, wear resistance, economy, etc. The arguable advantage has become the leading product of FAG bearing industry. The following are the application characteristics and advantages of some self-lubricating FAG bearings:

Oil-free lubricated FAG bearing series

1.No oil lubrication or less oil lubrication, suitable for places where it is impossible to add oil or it is difficult to add oil. It can be used without maintenance or with less maintenance.

2.Good wear resistance, small friction coefficient and long service life.

3.There is an appropriate amount of elastoplasticity, which can distribute stress on a wider contact surface and improve the bearing capacity of FAG bearings.

4.The static and dynamic friction coefficients are similar, which can eliminate crawling at low speed, thereby ensuring the working accuracy of the machine.

5.It can make the machine reduce vibration, reduce noise, prevent pollution and improve working conditions.

6.A transfer film can be formed during operation, which protects the grinding shaft without biting.

7.The hardness of the grinding shaft is low, and shafts without tempering treatment can be used, thereby reducing the difficulty of processing related parts.

8.Thin wall structure, light weight, can reduce the mechanical volume.

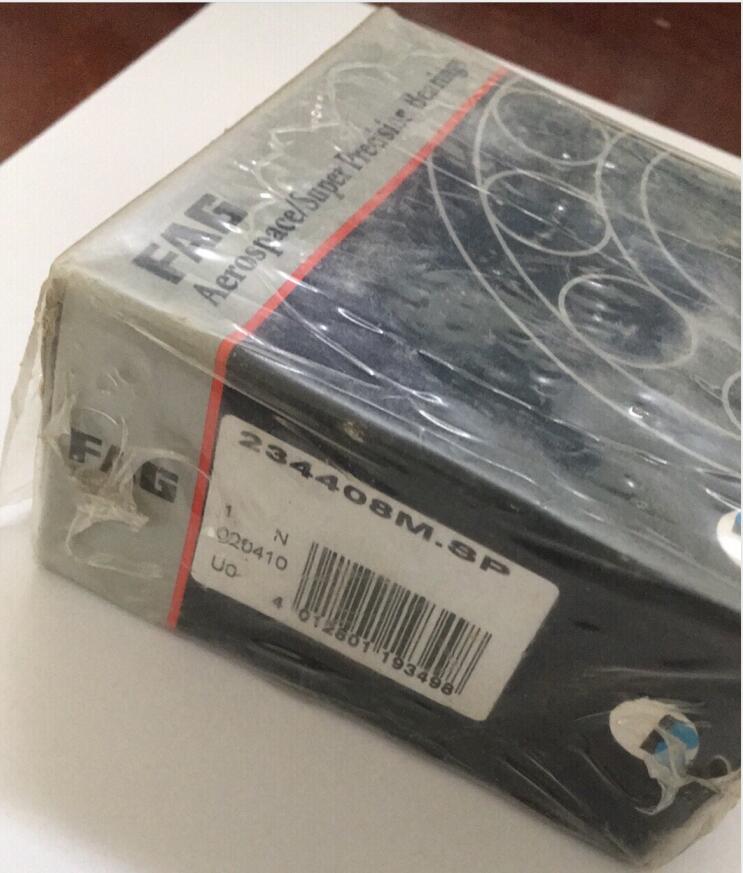

9. A variety of metals can be electroplated on the back of the steel, which can be used in corrosive media; it has been widely used in sliding parts of various machinery, such as printing machines, textile machines, tobacco machinery, micro motors, automobiles, motorcycles and agricultural and forestry machinery and many more. FAG 234408 M.SP online , pls click here :

Introduction of boundary lubrication self-lubricating FAG bearing series

1.Good bearing capacity and good wear resistance.

2.It is suitable for the rotation movement, swing movement under high load and low speed, and the occasions where the opening and closing are frequent under load and it is not easy to form hydrodynamic lubrication.

3.Under the condition of boundary lubrication, it can be maintained without oil for a long time, and adding oil in the over layer makes the service life of FAG bearings longer.

4.The surface plastic layer can be left with a certain margin during processing and molding. After assembly and pressing into the seat hole, it can be processed by itself to achieve a better assembly size.

5.The products are mainly used in automobile chassis, metallurgical machinery, mining machinery, water conservancy machinery, construction machinery, agricultural machinery, steel rolling equipment, etc. JDB solid inlaid FAG bearing series JDB solid inlaid FAG bearing series is a universal basic product, regardless of high pressure, low pressure, high temperature, low temperature, oil lubrication, oil-free lubrication or water lubrication, can adapt. The base body of the product is high-strength brass, which has doubled the hardness of the general copper sleeve and more than doubled the wear resistance. Widely used in: light industry machinery, heavy industry machinery, construction machinery, metallurgy machinery, transportation machinery, etc., such as: continuous casting machine, rolling mill, injection molding machine, paper machine, mold guide column, ship, machine tool, etc.

Introduction to the 5 damage states of common FAG bearings

1.Mechanical damage

In severe cases, metal peeling and large-scale chaotic scratches occur on the contact surface; under normal circumstances, FAG bearing mechanical damage refers to the appearance of groove marks on the alloy surface of the bearing shell. The main reason for the damage of the contact surface and the ablation phenomenon to cause mechanical damage to the bearing is that the FAG bearing surface is difficult to form an oil film or the oil film is severely damaged.

2.Bearing pitting

Plastic deformation and cold work hardening of the outer surface layer, sliding FAG bearings under the impact of cylinder pressure impact load) repeatedly. Partially lose the ability to deform, gradually form lines and continue to expand, then as the debris falls off, the outer surface layer of the load forms holes. Generally, when pitting corrosion occurs on the bearing bush, pits first appear, and then the pits gradually expand and cause cracking at the interface of the alloy layer.

The cracks extend along the parallel direction of the interface until they are peeled off. The main reason for the erosion of the sliding bearing is that the cross-section of the structural elements such as the oil groove and the oil hole suddenly changes to cause a strong turbulence in the oil flow. The turbulent oil flow forms a bubble in the vacuum area, and then the bubble rises due to the pressure increase and the bubble collapse. Cavitation generally occurs in the high load area of FAG bearings, such as the lower bearing shell of the main FAG bearing of the crankshaft.

3.Fatigue pitting

Due to engine overloading, FAG bearing fatigue pitting is referred to. It makes the bearing work overheated and the FAG bearing gap is too large, causing fatigue damage, fatigue pitting or fatigue shedding in the middle of the bearing. Most of this damage is caused by overloading, excessive F-bearing clearance, or unclean lubricating oil and foreign matter in it. Therefore, when using it, care should be taken to prevent FAG bearings from overloading.

Do not run at too low or too high speeds; adjust the engine to a stable state when idling; ensure normal FAG bearing clearance to prevent engine speeds from being too high or too low; check, Adjust the working condition of the cooling system to ensure that the working temperature of the engine is appropriate.

4.FAG bearing alloy corrosion

The chemical impurities (acidic oxides, etc.) contained in the lubricating oil oxidize the bearing alloy to generate acidic substances. FAG bearing alloy corrosion is generally due to the impureness of the lubricating oil. Cause the bearing alloy to partially fall off, forming irregular tiny cracks or small pits. The main reasons for FAG bearing alloy corrosion are improper selection of lubricating oil, poor corrosion resistance of FAG bearing data, or rough operation of the engine and excessive temperature.

5.FAG bearing melting

Local high temperature is formed, and there is a tiny convex metal surface directly contacting between the journal and the friction pair of the bearing. In case of lack of lubrication and poor cooling, the FAG bearing alloy is blackened or partially melted. This failure is often caused by the over-tightening of the journal and the bearing; the lack of lubricating oil pressure can also easily burn the FAG bearing .

Tel: 00852-30697500

Fax: 00852-30697511

Email: sales@ericbearing.com

Message: Click Here Message!